Eyewash station

For enhanced safety in labs and industrial settings, opt for our Eyewash Stations, including Portable Eye Wash Units. Each unit meets stringent safety standards and industry certifications, ensuring reliable and compliant emergency eye care. Choose our solutions for dependable workplace safety.

Enlighteningpallet Eyewash Stations

Enlighteningpallet brings you superior Eyewash Stations, meticulously engineered for safety and efficiency in industrial and laboratory environments. Our stations are designed to meet the stringent safety standards required in hazardous settings, ensuring rapid and effective eye decontamination.

Enlighteningpallet Eyewash Stations are not just compliant with ANSI, NFPA, EPA, and CE certifications; they represent our commitment to providing reliable and user-centric safety solutions. Trust in our expertise for enhancing the safety standards in your workplace.

Eyewash Station Solutions by Enlighteningpallet

8Gal(30L) Eyewash Station

15Gal(53L) Eyewash Station

16Gal(61L) Eyewash Station

Wall-Mounted Eyewash Stations

Pedestal (Freestanding) Eyewash Stations

Combination Eyewash Stations

Obtain In-Depth Product Information and Pricing

The Comprehensive Guide to Eyewash Stations

In environments where the risk of chemical exposure is high, such as in petrochemical and hazardous material management, Eyewash Stations, including portable and emergency options, are indispensable for ensuring eye safety. Constructed to withstand demanding conditions, these eyewash stations are often made from materials that guarantee durability and resistance to corrosive substances.

This guide delves into the various aspects of Eyewash Stations, focusing on features, usability, and types, particularly Portable Eyewash Stations and Emergency Eyewash Stations. It’s designed to aid procurement specialists in understanding the critical role these stations play in safety protocols, aligning with stringent quality and certification requirements.

Our Eyewash Stations are endorsed by industry-specific certifications like ANSI, NFPA, EPA, and CE, demonstrating compliance with the highest safety standards. They come with an extensive warranty and offer customization options to meet unique operational needs.

Read on to learn how Eyewash Stations, both portable and emergency, become an essential part of effective safety and spill management strategies, providing immediate and adequate eye decontamination in critical situations.

Where Eyewash Stations Are Essential

For procurement specialists focusing on environmental safety, Eyewash Stations, including Pedestal, Wall Mounted, and Portable Eye Wash Units, are critical in various sectors:

- Petrochemical Operations: Where exposure to harsh chemicals is a frequent risk.

- Hazardous Material Handling: For instant eye cleansing in case of accidental splashes.

- Chemical Processing: Critical for quick response to chemical exposures.

- Pharmaceutical Facilities: Ensuring eye safety in sterile and controlled environments.

- Oil and Gas Supply Chains: Key for on-site safety in processing and transportation.

- Waste Management: For protection against potential chemical and biohazard exposure.

- Mining Sites: Where dust and small particles pose a constant risk to eye safety.

Key Components of Eyewash Stations

Eyewash stations, essential in emergency eye care, vary in design and features, but typically share three fundamental components. The specific attributes of each component can differ, influenced by factors such as the type of environment they’re used in, the nature of potential eye contaminants, and the station’s specific application. These components are particularly pertinent in designs like Pedestal Eyewash Stations, Wall Mounted Eye Wash Stations, and Portable Eye Wash Units.

Spray Heads

These provide a controlled, gentle flow of water, crucial for safely rinsing chemicals or debris from the eyes without causing further irritation.

Control Valve

This vital component allows for the quick opening or closing of the water flow. It’s designed for ease of use, often requiring minimal effort to activate in an emergency.

Water Supply Pipe

This part ensures a steady and reliable supply of water to the station. It’s essential for the consistent operation of the eyewash station, especially during prolonged use.

Support Bracket or Base

Provides the necessary stability and structural integrity for the eyewash station, whether it’s a wall-mounted, pedestal, or portable unit. This component is crucial for ensuring the station remains firmly in place during use.

Drainage System

A key post-use feature, the drainage system efficiently handles wastewater, preventing the build-up of residues and reducing slip hazards in the area surrounding the station.

Signage and Instruction Labels

Clear and conspicuous signage and labels are essential for quickly identifying the eyewash station’s location. Instructions for use, prominently displayed, ensure users can operate the station effectively in an emergency.

Operational Mechanics of Eyewash Stations

In environments like petrochemical facilities, laboratories, and chemical processing areas, Eyewash Stations are essential for eye safety. Their operation is tailored for immediate and effective response to eye emergencies:

- Targeted Fluid Delivery: Designed with nozzles to direct a gentle water flow, efficiently flushing contaminants from the eyes.

- Quick Activation Mechanism: Easy-to-use levers or buttons allow for immediate water flow, essential in emergencies.

- Durable, Anti-Corrosive Build: Constructed with corrosion-resistant materials to withstand harsh chemicals.

- Controlled Water Flow: Ensures a consistent, tepid water supply for a sufficient duration, crucial for effective eye rinsing.

Key Considerations for Procuring Eyewash Stations

Procuring the right eyewash station involves several important considerations to ensure safety and compliance in your facility

Facility Layout and Employee Numbers

Assess your facility’s design and workforce size to determine the type and quantity of eyewash stations needed. The station’s location and accessibility based on potential hazards and employee proximity are crucial

Adherence to ANSI Z358.1 Standards

Your eyewash station selection should conform to ANSI Z358.1 guidelines. This includes positioning the station within 10 seconds (or 55 feet) of potential hazards and ensuring it can provide 15 minutes of continuous flushing

Portability for Dynamic Environments

The flexibility of portable, self-contained eyewash stations is significant, especially in changing work environments. Portable units offer the advantage of being easily relocated as needed

Accessibility Compliance

Select eyewash stations that meet accessibility standards, including proper knee and toe clearance for a forward approach and nozzle height compliance as per ADA Standards

Types of Eyewash Stations and Their Applications

Eyewash stations play a critical role in ensuring the safety and well-being of employees, especially in workplaces where there is a risk of exposure to hazardous substances. These specialized stations are designed to provide immediate decontamination to the eyes, helping to prevent injury from chemicals, particles, or other harmful materials. Given the diverse nature of industrial and laboratory environments, there’s a variety of eyewash stations available, each tailored to meet specific operational needs and safety standards. From permanent fixtures in chemical plants to portable units in dynamic construction sites, these stations are an indispensable part of safety protocols, providing rapid and effective eye cleansing to mitigate the risks associated with hazardous material exposure. Their presence and accessibility are crucial not only for compliance with health and safety regulations but also for fostering a safe and responsible work environment.

Portable Eyewash Stations:

- Description: Equipped with a self-contained fluid reservoir, these stations can be easily relocated as needed. They are often activated manually and deliver a controlled flow of flushing fluid.

- Suitable for: Temporary work sites, construction areas, or facilities where plumbing is not available or fixed installations are not feasible.

Benchtop or Wall-Mounted Eyewash Stations:

- Description: Compact units that can be mounted on walls or benchtops. They are ideal for areas with limited space but still provide effective eye flushing capabilities.

- Suitable for: Smaller facilities or confined workspaces, such as school laboratories, clinics, or small manufacturing units.

Drench Showers with Eyewash Units:

- Description: Combination units that feature both a full-body drench shower and an eyewash station. They are designed to provide comprehensive decontamination in the event of large-scale chemical exposure.

- Suitable for: Environments with high risks of extensive chemical spills or splashes, where both body and eye decontamination may be necessary.

The Difference Between Portable and Combination Eyewash Stations

Purpose & Function

- Portable Eyewash Stations: Designed for flexibility and mobility, these stations are equipped with their own fluid reservoir, making them ideal for locations without direct water supply. They can be easily relocated to high-risk areas as needed.

- Combination Eyewash Stations: Typically include both an eyewash unit and a drench shower. These are fixed installations, providing comprehensive emergency decontamination for both eyes and body.

Material Composition

- Portable Eyewash Stations: Often made with lightweight yet durable materials to facilitate mobility. They need to be sturdy enough to hold the fluid reservoir.

- Combination Eyewash Stations: Constructed from robust materials like stainless steel or corrosion-resistant plastics, as they are permanent fixtures exposed to various environmental conditions.

Regulatory Credentials

- Portable Eyewash Stations: Must comply with safety standards for the volume and flow of flushing fluid, despite their portability.

- Combination Eyewash Stations: Adhere to stringent industry standards for both eyewash and shower capabilities, ensuring they provide adequate flow and pressure for decontamination.

Applicable Sectors

- Portable Eyewash Stations: Suitable for construction sites, temporary workspaces, or areas where the hazards are not fixed and may require moving the station closer to potential incident sites.

- Combination Eyewash Stations: Ideal for permanent industrial settings like chemical plants, laboratories, or facilities where the risk of extensive chemical exposure is high.

Warranty & Adaptability

- Portable Eyewash Stations: Typically come with a warranty and are adaptable to various environments due to their mobility.

- Combination Eyewash Stations: Offer a more extended warranty due to their permanent nature and are less adaptable once installed.

Financial Considerations

- Portable Eyewash Stations: Generally more cost-effective and a practical choice for temporary or changing work environments.

- Combination Eyewash Stations: Represent a larger initial investment but provide a comprehensive safety solution, particularly in environments with heightened risk of chemical exposure.

Understanding these differences is crucial for making an informed decision about which type of eyewash station best suits your specific workplace needs. Each type offers unique benefits, tailored to various industrial and environmental requirements

.

Essential Procurement Considerations for Eyewash Stations

When procuring eyewash stations for your facility, it’s essential to consider various factors to ensure you select the right type and model that aligns with your specific safety requirements and operational environment. Here are key aspects to keep in mind:

Decide between portable, plumbed, combination (eyewash and shower), pedestal, and wall-mounted units based on your workplace layout and the nature of hazards present.

Ensure the eyewash station meets relevant safety standards, such as ANSI Z358.1, for effective emergency eye flushing.

Consider the installation process and the accessibility of the station, ensuring it’s within the required distance from potential hazard areas.

Assess the water supply system, especially for plumbed units, and the quality of water, including temperature control and flow rate.

Understand the maintenance needs of the eyewash station to ensure it remains functional and hygienic for emergency use.

Check the construction materials for durability, especially in harsh industrial environments where corrosion resistance might be necessary.

Evaluate the ease of operation, particularly the activation mechanism, to ensure quick and simple use during emergencies.

Factor in the available space in your facility to accommodate the eyewash station without obstructing workflow.

Choose a reputable supplier with a proven track record for quality products and reliable customer support.

Balance the initial cost against long-term benefits, including durability, maintenance costs, and compliance with safety regulations.

By carefully considering these factors, you can select an eyewash station that not only meets regulatory requirements but also addresses the specific safety needs of your workplace.

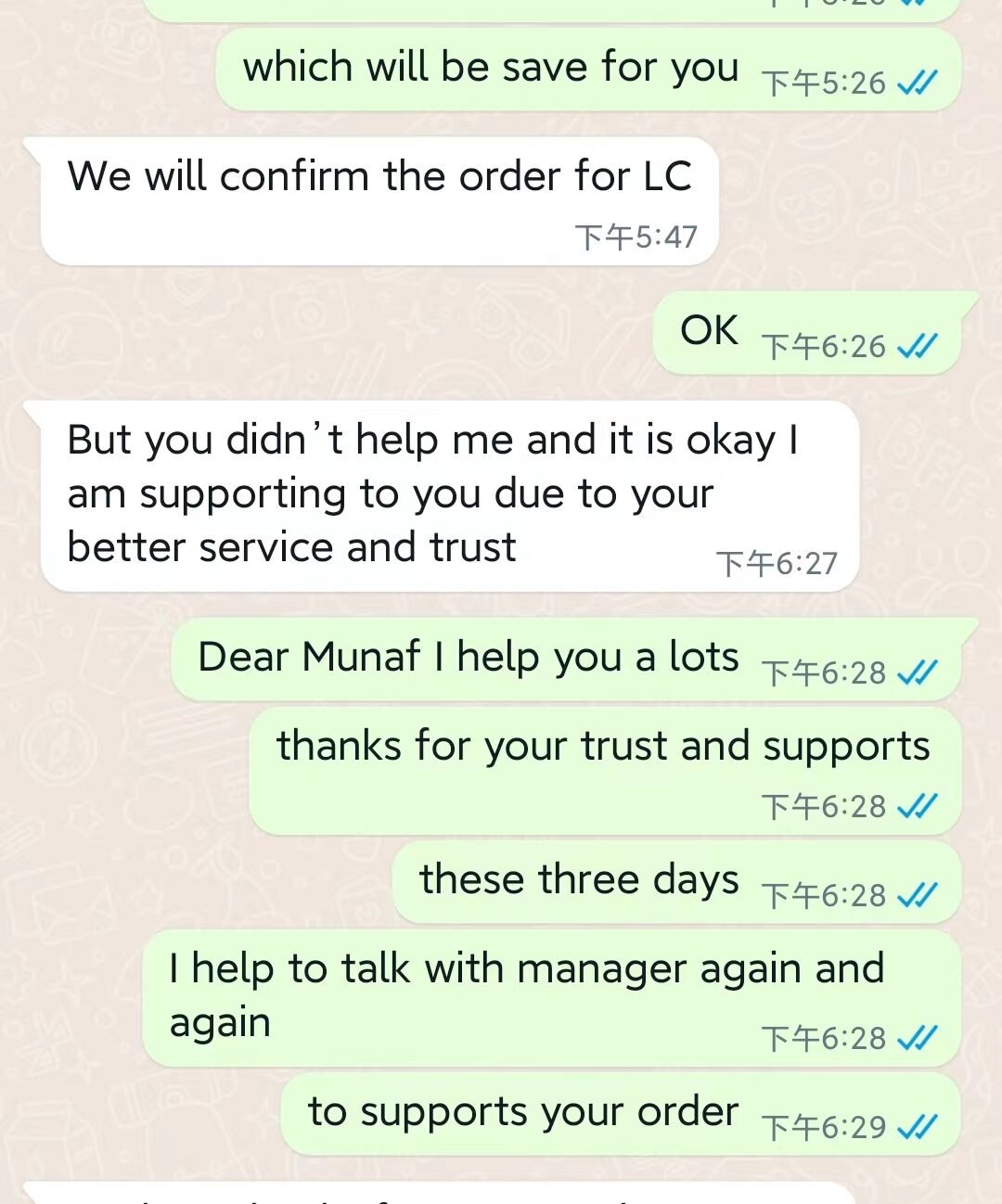

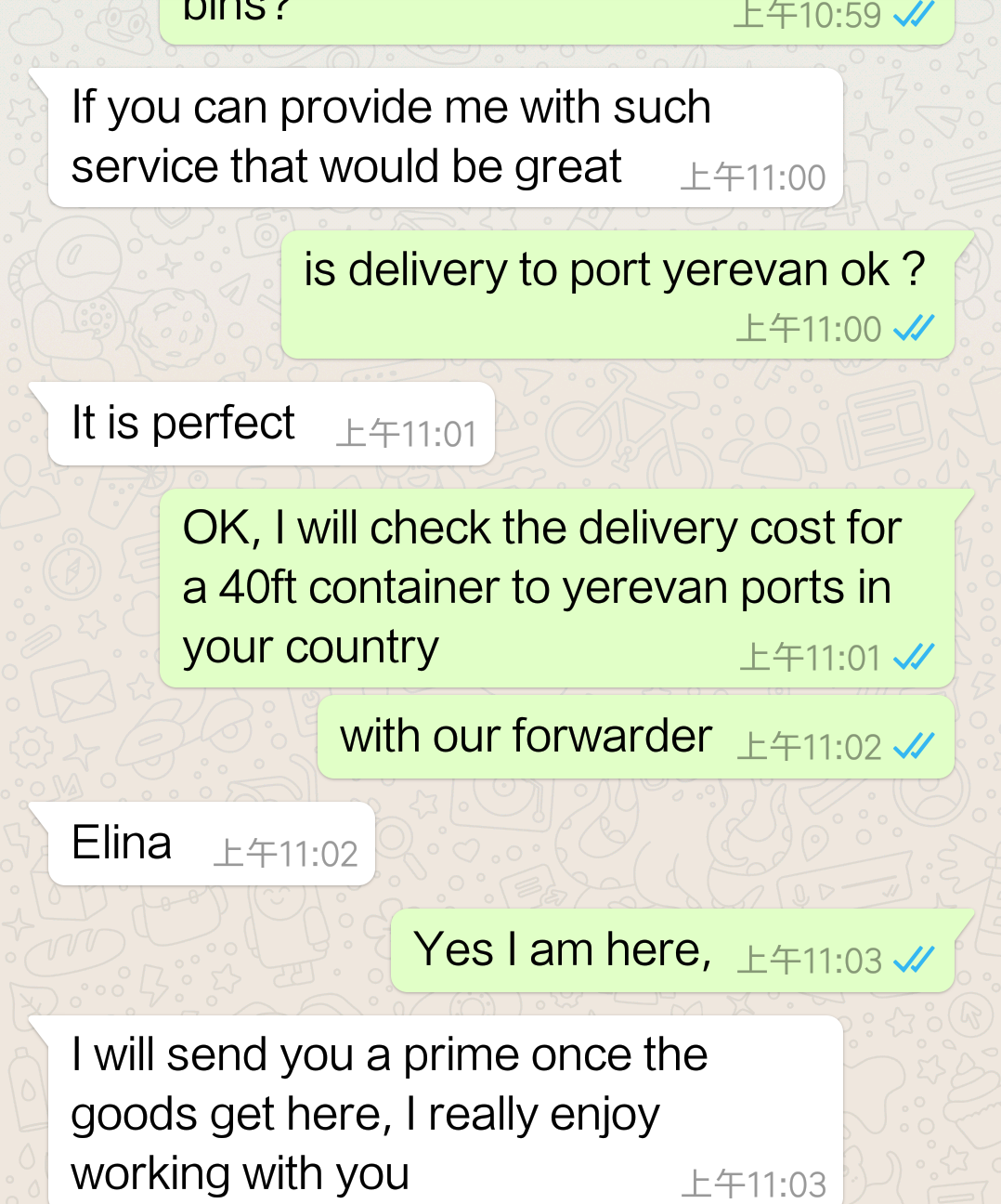

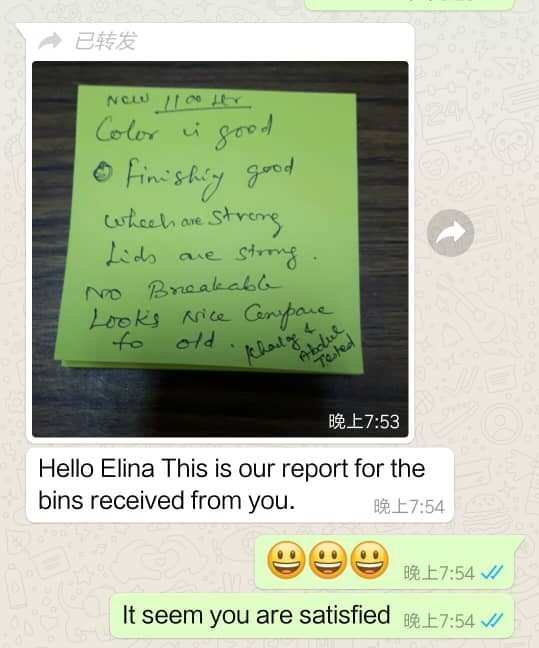

What Our Satisfied Customers Are Saying

Certified Quality and Efficiency: Your Competitive Edge

Our robust manufacturing capabilities and stringent quality controls are backed by prestigious certifications such as ANSI, NFPA, EPA, and CE. We set the industry benchmark, ensuring that your business leverages only the best in spill containment solutions.

How We Works

Quote Generation

Receive a customized quote that aligns with your budget and specifications.

Order Confirmation

Approve the quote and finalize the order details.

Production

Your order is crafted to meet high quality and certification standards.

Quality Check

Each product undergoes rigorous quality assurance tests.

Shipment

Experience seamless logistics as your order is dispatched for timely delivery.

Connect for Unparalleled Benefits

Elevate Your Procurement: Get a Free Industry-Leading Spill Containment Catalog

Submit an inquiry today to receive our complimentary, top-tier spill containment catalog. Ideal for procurement experts in the petrochemical sector.

Elio Yu

- qingdao.shandong.China

- +86 131 5636 9052

- elio@cnplasticpallet.com

Call-to-Action for Inquiries

Get a Custom Quote Today for Spill Containment Pallets and Eyewash Stations—Achieve Safety and Compliance Now