Spill Containment Pallets

Select Enlightening Pallet for premium Lab Spill Containment Pallets, standard Spill Containment Pallets, and IBC Spill Pallets. Whether off-the-shelf or customized, our products are in strict compliance with industry certifications. Engage with us for solutions precisely aligned with your operational needs.

Spill Containment Pallets

Enlighteningpallet: Pioneering Excellence in Spill Containment Solutions.Established as a leader in the industry, Enlightening Pallet operates with state-of-the-art German machinery and automated robotics, featuring in-house R&D and specialized design teams. We are focusing on Spill Containment Pallet wholesale trading with minimal retail involvement, and hold multiple certifications including ANSI, NFPA, EPA, and CE.

Favored by procurement experts like Missebo Equipe, we export spill bunds to Middle East, Southeast Asia, Australia, South America. Our products are engineered for the unique needs of petrochemical and hazardous material handling.

Select Enlighteningpallet for superior quality, tailored solutions, and an extensive warranty exceeding three years.

Spill Containment Solutions By Enlightening Pallet

Lab Spill Containment Pallets

Compact, durable, and efficient for spill safety in laboratories.

Spill Containment Pallet

large-capacity spill management and easy forklift access

IBC Spill Pallet

pecifically engineered for large IBC container handling with convenient forklift access.

Obtain In-Depth Product Information and Pricing

The Comprehensive Guide to Spill Containment Pallets

In the high-stakes field of petrochemical and hazardous material management, Spill Containment Pallets serve as critical components for environmental safety and effective spill control. Manufactured from high-grade, acid and alkali-resistant HDPE material, these pallets stand as a paragon of durability and functionality.

This guide provides an in-depth exploration into the features, components, and classifications of drum Spill Containment Pallets. Aimed at helping procurement specialists gain a comprehensive understanding, the information aligns well with quality-focused, certification-based, and efficient procurement strategies.

With endorsements from industry-specific certifications such as ANSI, NFPA, EPA, and CE, these spill containment pallets meet and exceed rigorous industry standards. Additional features include a 3+ year warranty and options for customization to suit particular requirements.

Continue reading to discover how drum pallet can serve as a vital component in a sound spill management strategy.

Where Spill Containment Pallets Are Essential

In your role as a procurement specialist, you’re constantly navigating sectors that require the highest standards for environmental safety and spill management. Recognizing your focus on quality, certifications, and logistics, you’ll find that Spill Containment Pallets are indispensable in various high-risk industries such as:

- Petrochemical Operations

- Hazardous Material Handling

- Chemical Processing

- Pharmaceutical Facilities

- Oil and Gas Supply Chains

- Automotive Sectors

- Waste Management

- Port and Maritime Activities

- Mining Sites

Key Components of Spill Containment Pallets

Drum Spill pallets, while rooted in common foundational elements and operating mechanisms, display nuances in their design and structure. Central to these pallets are three predominant components. The design intricacies and attributes of each part can diverge based on considerations like choice of resilient materials, nature of the chemicals they manage, their specific application, and other salient determinants.

Grid-Like Surface for Efficient Liquid Drainage

The first component of a spill containment pallet features a grid-like surface design that serves a critical function in facilitating the effective management of spilled liquids. This specially engineered grid structure is strategically integrated into the pallet’s construction to ensure that any leaked or spilled fluids are efficiently channeled downward into the lower containment tray. This design enhancement optimizes the pallet’s spill containment capabilities, providing an extra layer of protection against environmental hazards.

Bottom Sump for Safe Containment of Petroleum and Chemical Liquids with Corrosion Resistance

The second integral component of the spill containment pallet is the bottom sump, a reservoir designed to securely contain petroleum or chemical liquids. Crafted with exceptional corrosion-resistant properties, this sump acts as a safeguard against potentially hazardous substances. Its purpose is to ensure that any spilled or leaked fluids are contained within the pallet, preventing environmental contamination and maintaining safety standards. This corrosion-resistant feature enhances the durability and reliability of the spill containment pallet when handling corrosive materials.

Bottom Drainage Outlet for Easy Disposal of Spilled Liquids

The third essential component of the spill containment pallet is the bottom drainage outlet. This feature is purposefully integrated to facilitate the straightforward disposal of leaked or spilled liquids. It enables the controlled and efficient pouring out of any contained fluids, ensuring the safe and proper management of potentially hazardous substances. This bottom drainage outlet enhances the practicality and user-friendliness of the spill containment pallet, making it a reliable solution for handling and disposing of spilled liquids.

Operational Mechanics of drum containment pallet

Within petrochemical, laboratory, and chemical environments, the spill containment pallets execute their role as follows:

Fluid Navigation:the pallet’s topography channels spills towards a designated zone.

Accumulation Mechanism: An underlying basin is engineered to capture and contain any inadvertent leaks, mitigating further dispersal.

Anti-Corrosive Attributes: Select models are fortified with materials that offer heightened resistance to corrosion, making them suitable for managing aggressive chemicals.

Precision Liquid Egress: Incorporated with a specialized outlet, ensuring a measured and safe liquid discharge, bolstering environmental security.

Key Factors to Evaluate When Acquiring Spill Containment Pallets

Sometimes, even relatively newer Drum containment pallets may not perform at their best. Why does this happen? The answer lies in understanding these spill containment pallet products. Knowing these considerations is a part of extending the lifespan of spill containment pallets

Chemical Resistance:

Foremost, the material should be innately resistant to an array of chemicals, ensuring it doesn’t degrade or compromise when in contact with aggressive substances.

Cleanability:

In scenarios of spills or leaks, the material should allow for hassle-free cleaning, ensuring no residue buildup that could compromise future containment.

UV Resistance:

Especially for pallets positioned outdoors or in areas with significant sunlight exposure, UV resistance ensures the material won’t weaken or become brittle over time.

Impact Resistance:

Given the dynamic nature of industrial environments, the material should be robust enough to endure accidental impacts without cracking or breaking.

Temperature Tolerance:

In diverse operational settings, the material should remain stable and maintain its integrity across varying temperature ranges, both high and low.

Environmental Considerations:

It’s highly advantageous if the chosen material is both eco-friendly and readily recyclable, profoundly aligning with global sustainability and environmental conservation goals.

Categorizing Spill Containment Pallet Types by Usage Environment

Plastic spill containment pallets are differentiated into three distinct types based on their application environment: lab spill trays, drum spill containment pallets, and IBC (Intermediate Bulk Container) spill containment pallets. Each type is meticulously designed to cater to specific containment requirements in diverse industrial settings. With their precision engineering, these pallets ensure optimal performance, durability, and safety across various applications.

Lab Spill Trays: Precision Engineering for Laboratory Safety

Lab spill trays are a cornerstone of containment in laboratory settings, crafted with precision to handle the exacting requirements of such environments. These trays play a pivotal role in mitigating the risks associated with inadvertent spills, leaks, or drips of volatile chemicals and reagents. By doing so, they not only protect the laboratory personnel but also preserve the integrity of the lab environment, ensuring uninterrupted research and experiments.

Drum Spill Containment Pallets: Advanced Containment for Complex Industrial Scenarios

Drum spill containment pallets are meticulously engineered to confront the intricacies of seepage, spills, and unexpected releases from industrial drums. Essential for establishments engaged in the storage and transportation of high-risk chemicals, solvents, or hydrocarbons in drum formats, these pallets epitomize the pinnacle of containment technology. Their deployment is pivotal in averting ecological disruptions and ensuring stringent compliance with industry-specific regulatory mandates.

Large Capacity Water Tank IBC Spill Pallets: Advanced Containment for High-Volume Liquid Storage

Drawing insights from cutting-edge industry research and best practices, the Large Capacity 1000L Water Tank IBC Spill Pallets have been meticulously developed to ensure maximum containment efficiency for voluminous 1000-liter water tanks and comparable containers. A byproduct of rigorous industry standards and innovative design principles, these pallets are pivotal for sectors requiring substantial liquid storage. They not only provide a secure containment solution but also meet stringent regulatory requirements, reinforcing the commitment to environmental safety and operational excellence.

The Difference Between Spill Containment Pallets and Standard Plastic Pallets

Purpose & Function

- Spill Containment Pallets: Exclusively engineered to mitigate spills and leaks from containers such as drums or IBCs, promoting a risk-free, pristine operational setting.

- Standard Pallets: Predominantly utilized for logistical purposes, including transportation and storage, with no inherent spill containment capabilities.

Material Composition

- Spill Containment Pallets: Constructed from robust, acid and alkali-resistant High-Density Polyethylene (HDPE) to withstand aggressive substances.

- Standard Pallets: Typically crafted from wood or conventional plastics, devoid of specific resistance characteristics.

Regulatory Credentials

- Spill Containment Pallets: Possess an array of industry accreditations including ANSI, NFPA, EPA, and CE, evidencing stringent adherence to quality and safety benchmarks.

- Standard Pallets: Generally lack dedicated certifications pertinent to spill containment.

Applicable Sectors

- Spill Containment Pallets: Optimal for professionals in the petrochemical sector, containment pallet distributors, and procurement enterprises.

- Standard Pallets: Employed universally across diverse sectors without a concentrated emphasis on spill containment requisites.

Warranty & Adaptability

- Spill Containment Pallets: Extend the advantage of bespoke tailoring and are accompanied by a warranty of 2+ years.

- Standard Pallets: Typically offer restricted adaptability and come with conventional warranty terms.

Financial Considerations

- Spill Containment Pallets: Although they command a premium initially, the prospects for long-range fiscal benefits in terms of ensuring safety and regulatory alignment are substantial.

- Standard Pallets: More budget-friendly at the outset but are devoid of specialized attributes crucial for managing potential spill-related hazards.

Comprehending these nuances is imperative for a judicious procurement choice. If your emphasis revolves around quality, credentials, logistical prowess, and payment flexibility, spill containment pallets undeniably emerge as the paramount alternative for your enterprise.

Interested in delving deeper into how spill containment pallets can strategically bolster your procurement strategy? We’re here to assist.

Essential Procurement Considerations for Ramps, Drum Dollies, and Spill Pallets

Your needs in spill containment require a sophisticated, well-integrated solution. Incorporating ramps, drum dollies, and spill pallets can elevate your spill containment system from adequate to exceptional. Below is the step-by-step guide tailored to your unique requirements:

- Prioritize spill pallets made from durable, acid, and alkali-resistant HDPE to ensure longevity and resistance against varying substances.

- Ensure the materials of ramps and dollies are robust and capable of handling the weight and type of drums you deal with.

- Assess the capacity required based on the volume and type of chemicals or hazardous substances you handle. Ensure the pallets, ramps, and dollies can handle the anticipated load.

- Dimensions matter. Ensure that the pallets fit within your facility’s space constraints and are compatible with the drums you use.

- Ensure that the products adhere to industry certifications such as ANSI, NFPA, EPA, and CE.

- Ramps should have non-slip surfaces and secure attachments to pallets, ensuring safe loading and unloading.

- Dollies should have lockable wheels to ensure stability during movement.

- Verify that the ramps can be easily attached to the spill pallets, and the dollies are compatible with both the drums and pallets.

- Consider modular systems that allow for easy expansion or reconfiguration based on evolving needs.

- Look for suppliers with a proven track record in the petrochemical industry. Consider seeking recommendations from peers or attending trade shows.

- Assess the vendor’s responsiveness, delivery timelines, and after-sales support.

- Given that every facility might have unique requirements, check if the vendor offers customization options for the pallets, ramps, and dollies.

- Custom solutions can help in better alignment with your specific operational needs.

- While price is a crucial factor, especially for procurement officers, ensure that you’re not compromising on quality. Remember, in spill management, a system’s reliability can significantly impact operational safety.

- Opt for products that come with a substantial warranty, indicating the manufacturer’s confidence in their product’s durability.

- Understand the delivery timelines. Delays in receiving essential equipment can disrupt operations.

- Assess if the vendor offers logistical support or if you need to make separate arrangements.

- Determine if the vendor provides training on the proper use and maintenance of the products.

- Regular training ensures that your team can effectively and safely use the spill management tools.

- As your business grows, your spill management needs may evolve. Consider products that are scalable and vendors who can support future expansions or upgrades.

By keeping these essential procurement considerations in mind, you can ensure that you select the most suitable ramps, drum dollies, and spill pallets for your facility, optimizing spill management and ensuring compliance with industry standards.

Optimizing Spill Management Using Ramps, Drum Dollies, and Pallets

- Start by assessing the quantity and type of chemicals or hazardous substances you handle. This will help determine the size and capacity of the spill containment tools you’ll need.

- Understand the workflow and traffic patterns in your facility to select the best placement for pallets and associated tools.

- Choose spill containment pallets that are made of durable, acid, and alkali-resistant HDPE to ensure longevity and resistance against the substances you deal with.

- Ensure the pallets have adequate capacity for the drums or containers they will hold, adhering to industry regulations.

- Ramps facilitate easy loading and unloading of drums onto the spill pallets. Ensure the ramps are sturdy and have a non-slip surface.

- Align the ramp with the pallet’s entry point. This not only streamlines operations but also reduces the risk of accidental spills during drum placement or retrieval.

- Drum dollies offer mobility, making it easier to transport drums across the facility without the need for specialized equipment.

- Ensure the dollies are compatible with the drums’ size and weight. The dolly should have smooth-rolling, lockable wheels to ensure stability during movement.

- Position the spill pallets in areas of maximum usage, ensuring they are easily accessible.

- Use drum dollies to transport the drums to the pallet’s location. Once in position, use the ramp to easily roll the drum onto the pallet.

- Regularly inspect the entire system – the pallets for any signs of wear or damage, the ramps for stability, and the dollies for smooth movement.

- Ensure that all personnel handling the drums are adequately trained. They should be familiar with the correct procedures for using ramps and dollies and understand the importance of spill management.

- Regular drills can help in reinforcing best practices and ensuring swift response in case of any spills.

- Regularly inspect and maintain all components. This includes checking the pallets for any signs of wear or damage, ensuring the ramps are stable and secure, and verifying that the dollies roll smoothly.

- Stay updated with the latest spill management solutions and technologies. Periodically assess if any upgrades or additions would benefit your system.

By following this guide and integrating ramps, drum dollies, and spill pallets, you can ensure efficient, safe, and compliant spill management in your facility. The combination of these tools not only enhances safety but also streamlines operations, ensuring that your business remains both productive and compliant with industry regulations.

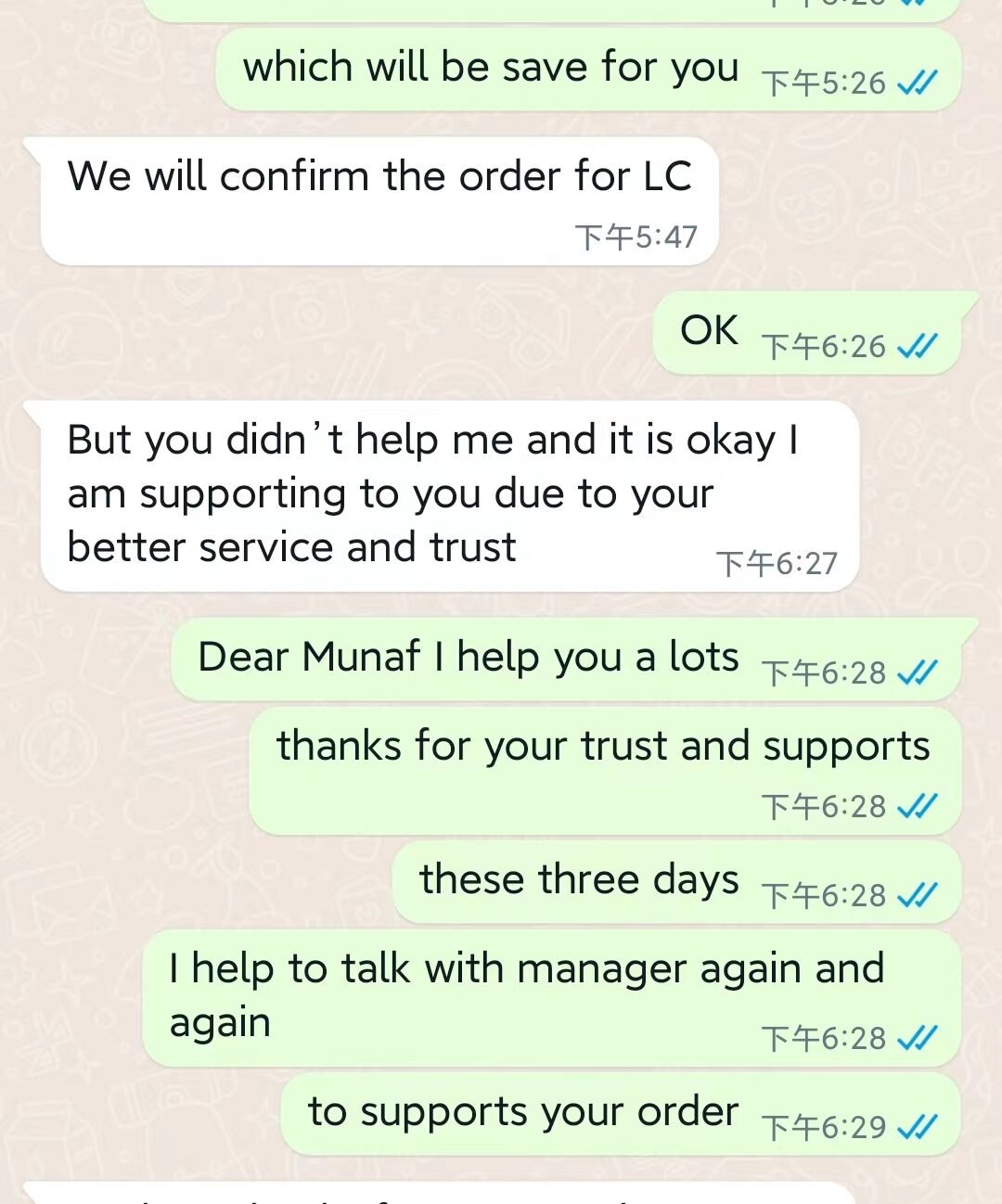

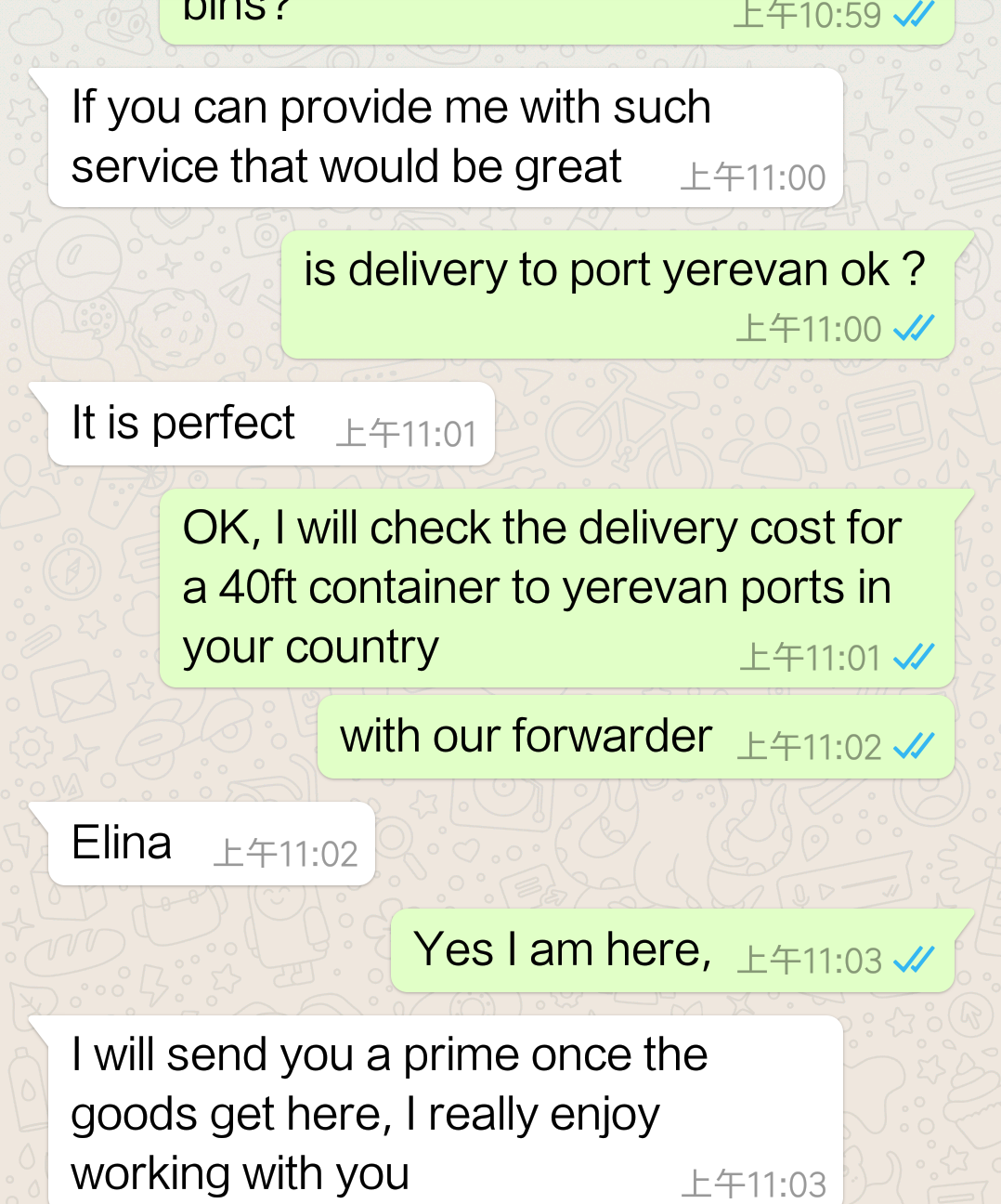

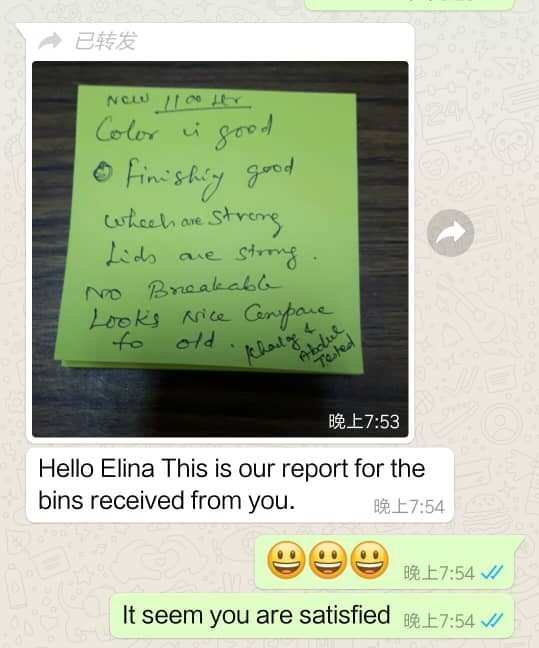

What Our Satisfied Customers Are Saying

Certified Quality and Efficiency: Your Competitive Edge

Our robust manufacturing capabilities and stringent quality controls are backed by prestigious certifications such as ANSI, NFPA, EPA, and CE. We set the industry benchmark, ensuring that your business leverages only the best in spill containment solutions.

How We Works

Quote Generation

Receive a customized quote that aligns with your budget and specifications.

Order Confirmation

Approve the quote and finalize the order details.

Production

Your order is crafted to meet high quality and certification standards.

Quality Check

Each product undergoes rigorous quality assurance tests.

Shipment

Experience seamless logistics as your order is dispatched for timely delivery.

Connect for Unparalleled Benefits

Elevate Your Procurement: Get a Free Industry-Leading Spill Containment Catalog

Submit an inquiry today to receive our complimentary, top-tier spill containment catalog. Ideal for procurement experts in the petrochemical sector.

Elio Yu

- qingdao.shandong.China

- +86 131 5636 9052

- elio@cnplasticpallet.com

Call-to-Action for Inquiries

Get a Custom Quote Today for Spill Containment Pallets and Eyewash Stations—Achieve Safety and Compliance Now