Spill Kits

Choose Enlighteningpallet for comprehensive Spill Kits, complete with essential absorbents, secure disposal bags, protective gear, and clean-up tools. Each kit is curated to meet rigorous industry standards and is ready for immediate deployment or customization to your specifications. Partner with us for certified, reliable spill management solutions that cater to the exacting demands of your operational environment.

Spill Kits

Enlighteningpallet is a benchmark of innovation in Spill Containment. Backed by sophisticated manufacturing capabilities, our in-house R&D and specialized design teams are at the heart of our operation. We focus on the B2B market, excelling in wholesale trade with selective retail engagement, all while holding esteemed certifications like ANSI, NFPA, EPA, and CE.

Esteemed by procurement authorities such as Missebo Equipe, we cater to a diverse international market, encompassing the Middle East, Southeast Asia, Australia, South America, and Africa. Our products are precision-engineered to meet the exacting demands of the petrochemical industry and hazardous material management.

Choose Enlighteningpallet for unmatched durability, the option for customized solutions, and an extensive 3+ years warranty, securing your operations with superior spill containment technology.

Spill Response Excellence with Enlighteningpallet's Comprehensive Spill Kits

Oil-only spill kits

Oil-only spill kits are suitable for all fuel, oil, petroleum,cooking oil and other messy liquid spills

Hazchem Spill Kits

Hazchem are designed for most hazardous chemical spills including acids, coolants, solvents and oils.

Universal Spill Kits

Universal spill kits handle maintenance, absorbing many liquids, including hydrocarbons and chemicals

Obtain In-Depth Product Information and Pricing

The Procurement Comprehensive Guide for Elite Spill Kits

For industry professionals navigating spill emergencies, Enlighteningpallet provides spill kits that balance premium performance with practicality. Ideal for petrochemical environments, these kits are curated to offer swift and reliable spill management.

Designed to meet the exacting needs of procurement officers, our spill kits combine high-quality absorbents and safety equipment, ensuring compliance with international standards. They are the result of rigorous R&D, backed by certifications that include ANSI, NFPA, EPA, and CE.

Recognizing the procurement focus on quality and cost, these kits offer an optimal balance. This guide is your pathway to understanding how our spill kits become essential in efficient spill response.

Spill Kits: Essential for Safety in High-Risk Industries

As a procurement officer focusing on environmental safety and spill management, the importance of Spill Kits cannot be overstated. Tailored to meet the demands of various high-risk industries, these kits are crucial for maintaining compliance, safety, and operational efficiency. They are particularly vital in sectors such as:

- Petrochemical Operations

- Hazardous Material Handling

- Chemical Processing

- Pharmaceutical Facilities

- Oil and Gas Supply Chains

- Automotive Sectors

- Waste Management

- Port and Maritime Activities

- Mining Sites

Composition of Spill Kits with Specific Components

Spill Control Kits designed for oil spill management typically comprise several specialized components, each serving a crucial role in the containment and clean-up process. The components in such a kit include

Oil Absorbent Pad

These pads are specifically designed to absorb oil and hydrocarbon-based fluids. They are usually lightweight and can be easily placed on or around a spill to quickly absorb the oil.

Oil Absorbent Roll

Similar to the pads, these rolls provide a larger coverage area and can be cut to size as needed, making them versatile for various spill sizes.

Oil Absorbent Sock

These are flexible tubes filled with absorbent materials, ideal for containing and absorbing spills around the base of machinery, along the perimeter of spills, or around leaky equipment.

Oil Absorbent Pillow

These are larger absorbent units, designed for absorbing high volumes of oil. They are particularly useful in areas where leaks are recurrent or in catch basins.

Operational Mechanics of Spill Kits

Chemical oil spill kits are designed for rapid and effective spill management in environments like petrochemical facilities and laboratories. Their operation includes:

Targeted Absorption: Utilizing pads, rolls, socks, and pillows specifically for oil and chemical spills.

Containment Strategy: Socks and booms confine spills, aiding in swift containment.

Chemical Safety: Components are selected for chemical resistance, ensuring safe handling.

Efficient Disposal: Disposal bags provided for environmentally safe removal of contaminated materials.

Protective Gear: Includes gloves for user safety during spill clean-up.

These kits are optimized for quick response to minimize the impact of chemical oil spills.

Essential Criteria for Selecting Emergency Spill Kits

When choosing Emergency Spill Kits, particularly Spill Kit Bags, for effective spill management, it’s crucial to consider several factors that influence their performance and longevity. Key aspects include:

Absorption Capacity

Ensure the kit contains enough absorbents (pads, rolls, socks, booms, pillows) to handle the volume of potential spills.

Chemical Compatibility

The materials in the kit, especially absorbents, should be compatible with the types of chemicals they are intended to manage.

Portability and Accessibility

Spill Kit Bags should be easily portable and accessible for quick response in emergency situations.

Containment and Clean-Up Tools

Ensure the kit includes necessary tools for spill containment and clean-up, like gloves, disposal bags, and safety gear.

Compliance with Regulations

The kit should meet industry-specific safety and environmental regulations.

Customization for Specific Needs

Consider if the kit needs to be customized for specific spill scenarios or environments.

Classifying Spill Kits by Their Application Environments

Spill kits, essential in managing spills in various settings, are categorized based on their specific usage environments. The main types include

Lab Spill Kits:

- Target Environment: Primarily for laboratories handling a range of chemicals.

- Key Components: Include precision absorbents like neutralizing pads, small pillows, and wipes. Safety equipment features goggles, acid-resistant gloves, and disposable lab coats.

- Special Attributes: Compact for easy storage in limited spaces. Components are resistant to a broad spectrum of laboratory chemicals, ensuring versatility and safety.

Industrial Spill Kits:

- Target Environment: Suited for manufacturing areas, warehouses, and facilities with high-volume liquid handling.

- Key Components: Comprise high-capacity absorbent materials such as large rolls, booms, and high-volume socks. Equipped with full-body protective gear, spill berms, and clean-up tools like scoops and disposal bags.

- Special Attributes: Often housed in wheeled bins or cabinets for quick access across large facilities. High absorption capacity and durability are key, providing comprehensive spill response solutions.

Outdoor Spill Kits:

- Target Environment: Ideal for construction sites, ports, and other outdoor or rugged areas.

- Key Components: Feature sturdy, oil-only and universal absorbents, along with all-weather gloves, steel-toed boots, and heavy-duty disposal bags.

- Special Attributes: Built to endure extreme weather conditions with UV-resistant and waterproof materials. The kits are often housed in rugged, sealable containers to protect contents from environmental elements.

Vehicle Spill Kits:

- Target Environment: Customized for trucks, shipping containers, and fleet vehicles.

- Key Components: Compact, easy-to-use absorbents like mini socks, pads, and cushions, accompanied by basic protective gear such as gloves and eye protection.

- Special Attributes: Designed for immediate response to in-transit spills. These kits are space-efficient, allowing for easy storage in vehicle compartments, and quick deployment in case of a spill.

Each variant of spill kit is meticulously put together to provide efficient, safe, and compliant handling of spills, tailored to the specific challenges and requirements of diverse work environments.

The Difference Between Spill Containment Pallets and Standard Pallets

Purpose & Function

- Specialized Spill Kits: Designed specifically for rapid and effective containment and clean-up of hazardous spills, especially in environments handling oils, chemicals, and other hazardous substances.

- Standard Petrochemical Cleaning Kits: Intended for general cleaning and maintenance in petrochemical settings, not necessarily equipped for emergency spill response.

Material Composition

- Specialized Spill Kits: Comprise high-quality, specialized absorbents like pads, socks, and booms, made from materials that are highly effective at absorbing oils and chemicals.

- Standard Petrochemical Cleaning Kits: Often include basic cleaning tools and supplies like detergents, wipes, and mops, which are not designed for hazardous spill containment.

Regulatory Credentials

- Specialized Spill Kits: Typically adhere to stringent safety and environmental regulations, designed for compliance in high-risk settings.

- Standard Petrochemical Cleaning Kits: May not have specific certifications related to spill management and environmental compliance.

Applicable Sectors

- Specialized Spill Kits: Essential for sectors that handle hazardous materials, including petrochemical, pharmaceutical, and industrial environments.

- Standard Petrochemical Cleaning Kits: More suited for general maintenance in industrial and petrochemical sectors, without the focus on emergency spill response.

Warranty & Adaptability

- Specialized Spill Kits: Offer customization for specific spill types and environments, often accompanied by robust warranties.

- Standard Petrochemical Cleaning Kits: Generally have limited adaptability for emergency spill scenarios, with standard warranty terms.

Financial Considerations

- Specialized Spill Kits: Represent a higher initial investment but provide critical capabilities for spill response, potentially saving costs related to spill-related damages and compliance fines.

- Standard Petrochemical Cleaning Kits: More cost-effective for routine cleaning but lack the specialized components necessary for effective spill management.

Understanding these differences is key to making informed procurement decisions. If your focus is on safety, regulatory compliance, and effective spill response, specialized spill kits offer a comprehensive solution for your needs.

Looking to integrate specialized spill kits into your operational safety strategy? Let’s discuss how these kits can enhance your approach to spill management and compliance.

Key Procurement Guidelines for Safety Spill Kits

When integrating Safety Spill Kits, Chemical Oil Spill Kits, Mobile Emergency Spill Kits, Portable Spill Kits, and Spill Response Kits into your spill containment strategy, consider these tailored factors for an efficient solution

- Select kits with components compatible with the chemicals you handle, ensuring materials like absorbents are effective for oil, chemical, or universal spills.

- Durability of containers and bags, especially for Mobile and Portable Kits, is vital for enduring harsh environments.

- Assess the size and absorbent capacity based on the typical volume and nature of spills in your facility. Ensure kits are adequate for your most demanding scenarios.

- Portable and Mobile Kits should be compact yet sufficient, balancing ease of movement with spill response effectiveness.

- Verify that kits meet relevant safety and environmental standards (ANSI, NFPA, EPA, CE).

- Components like gloves, goggles, and other protective gear should be compliant with safety regulations.

- Ensure that Mobile and Portable Kits are easy to deploy and that components are accessible and straightforward to use during an emergency.

- Consider kits that offer a clear, organized layout for quick response.

- Choose vendors known for quality spill response products, preferably with experience in the petrochemical industry.

- Evaluate vendor reliability in terms of product availability, delivery, and customer support.

- Seek suppliers offering customization options for kits to match specific needs of your operation.

- Flexible solutions are crucial for adapting to changing requirements or spill types.

- Balance initial cost with long-term value; quality kits can prevent costly spill-related incidents.

- Look for warranties that assure product durability and reliability.

- Confirm delivery timelines to avoid operational disruptions.

- Evaluate if the supplier provides logistical support for large or specialized orders.

- Inquire about training programs for your staff on the use of Spill Kits.

- Regular training ensures effective, safe utilization of spill response equipment.

- Consider scalability of kits for future expansion or upgrades as your operational needs evolve.

- Evaluate the potential for adding additional components or larger kits as part of your long-term spill response strategy.

By focusing on these guidelines, you can select the most appropriate Safety Spill Kits, Chemical Oil Spill Kits, Mobile Emergency Spill Kits, Portable Spill Kits, and Spill Response Kits for your facility, enhancing your spill management efficiency and ensuring compliance with industry standards.

Enhancing Spill Management with Spill Kits

Incorporating Spill Containment Kits and Industrial Chemical Oil Spill Absorbent Cotton Pads

- Begin by evaluating the types and quantities of chemicals or hazardous substances handled in your facility. This assessment will guide the selection of appropriately sized and specialized spill kits.

- Consider the layout and traffic patterns within your facility to strategically place spill kits for maximum accessibility and efficiency.

- Opt for Spill Containment Kits that include high-grade, acid, and alkali-resistant absorbents suitable for the chemicals at your facility.

- Ensure the kits have a variety of absorbents like pads, socks, pillows, and booms to handle different spill sizes and types. Industrial Chemical Oil Spill Absorbent Cotton Pads are essential for oil-based spills.

- Place spill kits in high-risk areas and points of frequent chemical handling to ensure immediate access in case of a spill.

- Consider portable and mobile spill kits for areas with dynamic operations or where fixed spill stations are impractical.

- Conduct regular training sessions for staff on the proper use of spill kits, focusing on rapid response and safety procedures.

- Encourage familiarity with the contents of the spill kits and their specific applications in different spill scenarios.

- Inspect spill kits periodically to ensure all components are intact, not expired, and ready for use.

- Establish a protocol for quick restocking of used or depleted items, maintaining the readiness of each kit.

- Integrate the use of spill kits into your existing safety and emergency response plans.

- Coordinate spill kit deployment with other safety measures like evacuation routes, first aid, and fire safety protocols.

- Regularly review and update your spill management tools and techniques. Stay informed about advancements in spill response technologies.

- Consider upgrading kits with newer, more efficient absorbents and tools as they become available.

By incorporating Spill Containment Kits and Industrial Chemical Oil Spill Absorbent Cotton Pads into your spill management strategy, you significantly enhance your facility’s ability to respond swiftly and effectively to spills. This proactive approach not only ensures compliance with safety regulations but also minimizes potential operational disruptions and environmental impacts.

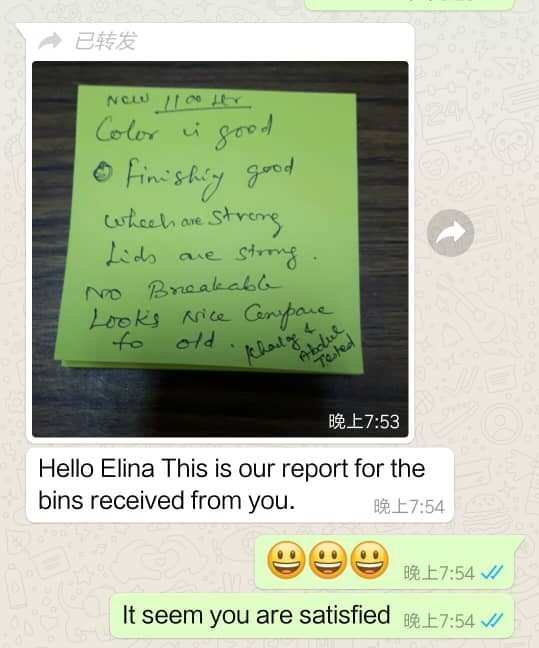

What Our Satisfied Customers Are Saying

Certified Quality and Efficiency: Your Competitive Edge

Our robust manufacturing capabilities and stringent quality controls are backed by prestigious certifications such as ANSI, NFPA, EPA, and CE. We set the industry benchmark, ensuring that your business leverages only the best in spill containment solutions.

How We Works

Quote Generation

Receive a customized quote that aligns with your budget and specifications.

Order Confirmation

Approve the quote and finalize the order details.

Production

Your order is crafted to meet high quality and certification standards.

Quality Check

Each product undergoes rigorous quality assurance tests.

Shipment

Experience seamless logistics as your order is dispatched for timely delivery.

Connect for Unparalleled Benefits

Elevate Your Procurement: Get a Free Industry-Leading Spill Containment Catalog

Submit an inquiry today to receive our complimentary, top-tier spill containment catalog. Ideal for procurement experts in the petrochemical sector.

Elio Yu

- qingdao.shandong.China

- +86 131 5636 9052

- elio@cnplasticpallet.com

Call-to-Action for Inquiries

Get a Custom Quote Today for Spill Containment Pallets and Eyewash Stations—Achieve Safety and Compliance Now